Welcome to Niral Automation

Welcome to Niral Automation Private Limited – your trusted partner in intelligent industrial automation solutions. We deliver scalable systems for machine control, testing, traceability, and Industry 4.0 integration using LabVIEW, PLC, C#, and Python.

WHAT WE DO!

Innovative Solutions

- Custom Software Development

- Programming Services

- Industry 4.0 & Traceability

- Vision-based Inspection Systems

- Onsite Programmer Deployment

- Training & Skill Development

Industry

We Serve

- Automotive

- Machine Builder

- Electrical Switchgear

- Electronics

- Aerospace

- Medical Devices

Technologies We Work With

- National Instruments Labview

- Siemens Allen-Brdley,Mitsubishi,Beckoff & other PLCs

- c#

- Python for,Reporting Ai and vision

OUR SERVICES

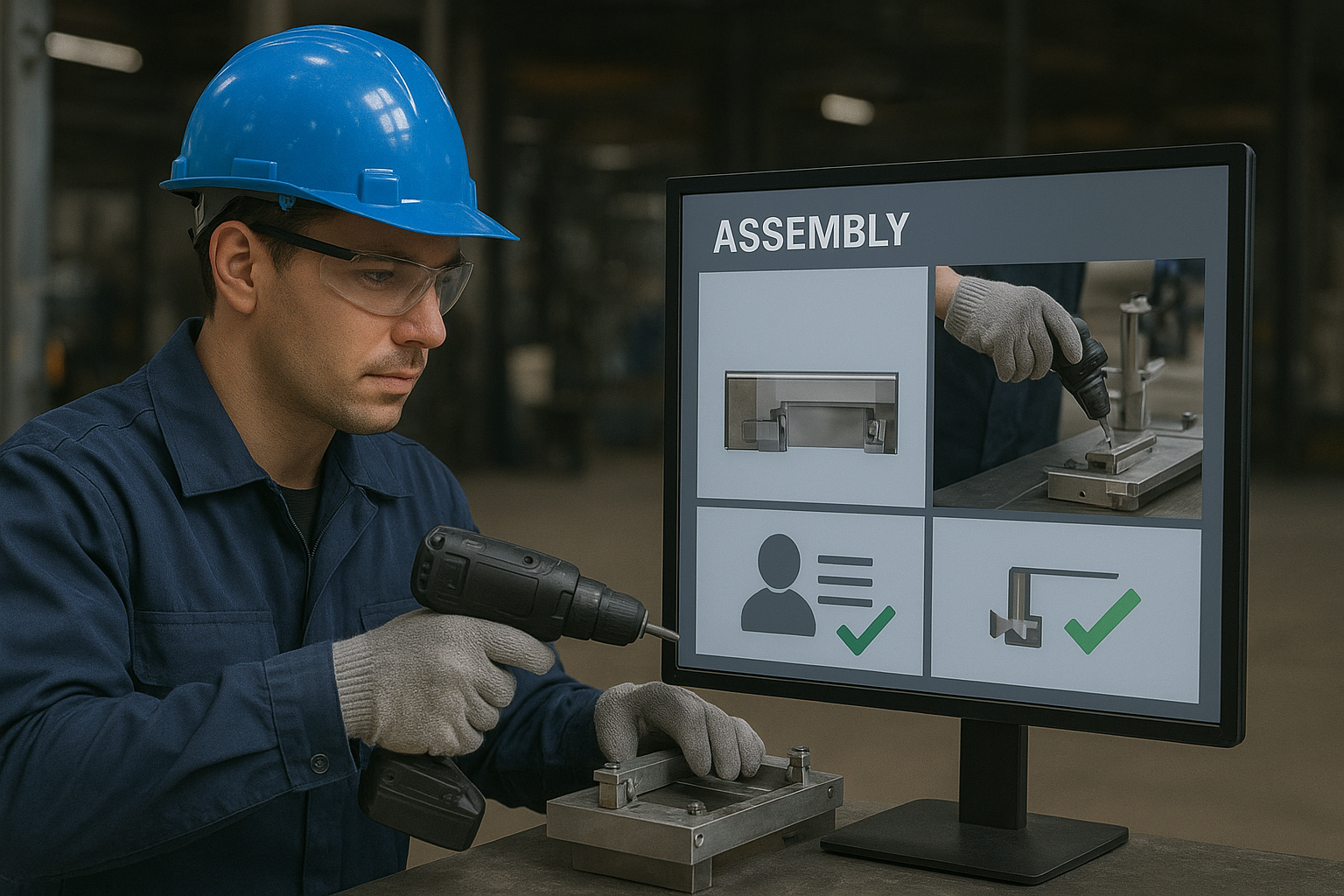

Turnkey Solutions

Complete software solutions for SPM machines, conveyor lines, test benches, and vision-based systems.

Programming Services

We deliver automation solutions using PLCs, LabVIEW, C#, and Python for machines, testing, and smart systems.

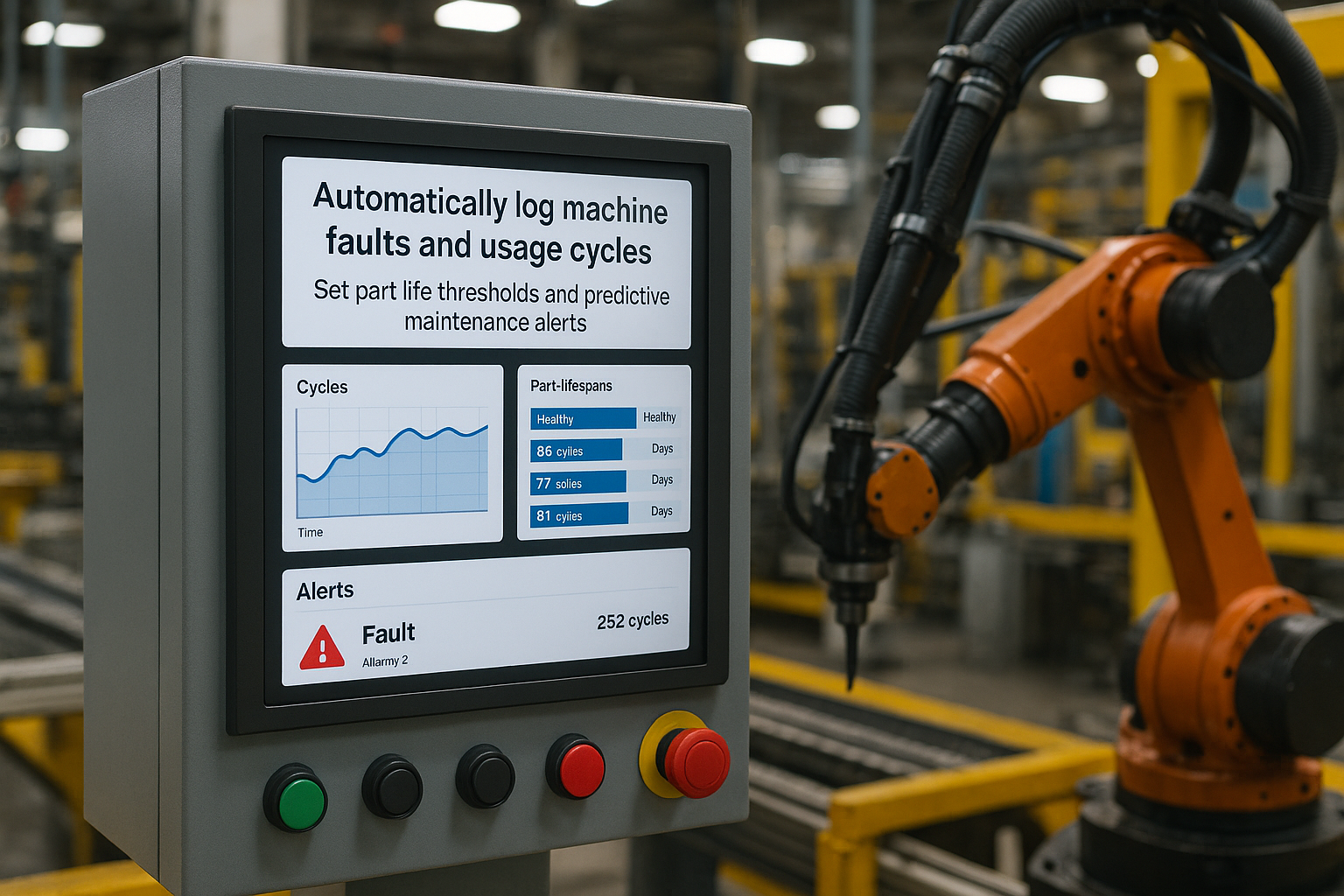

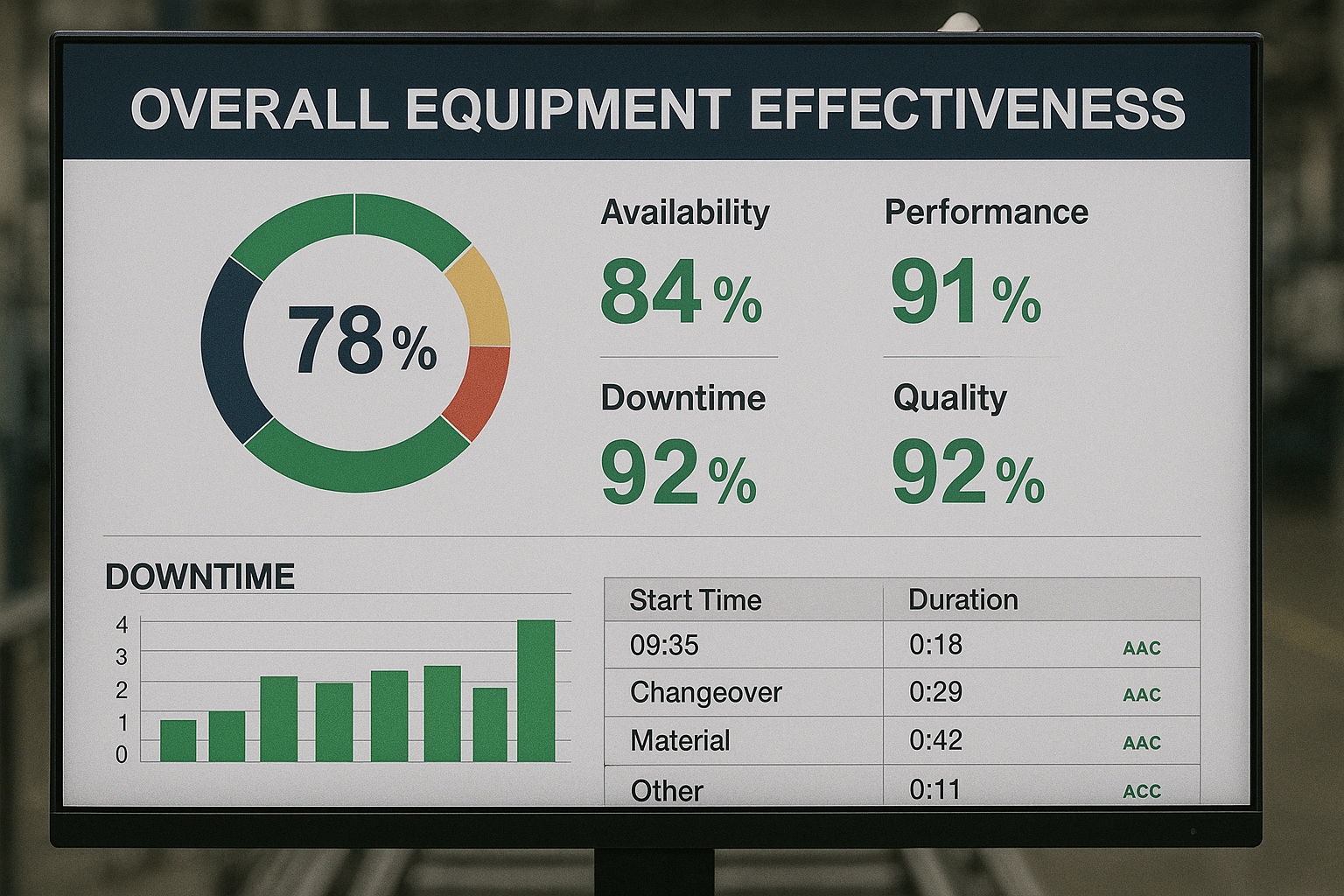

Industry 4.0

Data acquisition, real-time monitoring, OEE, error logging, and full production traceability.

Data Logging & Reporting

Automated data capture and reporting systems for production, test, and traceability data delivered in Excel, PDF, and server-stored formats.

Vision Inspection Systems

Integration of industrial vision systems for defect detection, alignment verification, dimensional checks, and traceability.

PRODUCT

We develop scalable, ready-to-deploy solutions for industrial environments

.png)