PLC

Programmable Logic Controller

A Plc (Programmable Logic Controller) is an industrial computer designed to automate electromechanical processes in manufacturing, production, and infrastructure systems. Below is a detailed breakdown of its primary purposes and applications.PLCs are built to withstand harsh industrial environments, including extreme temperatures, humidity, dust, and electrical noise.

Core Purposes of a PLC

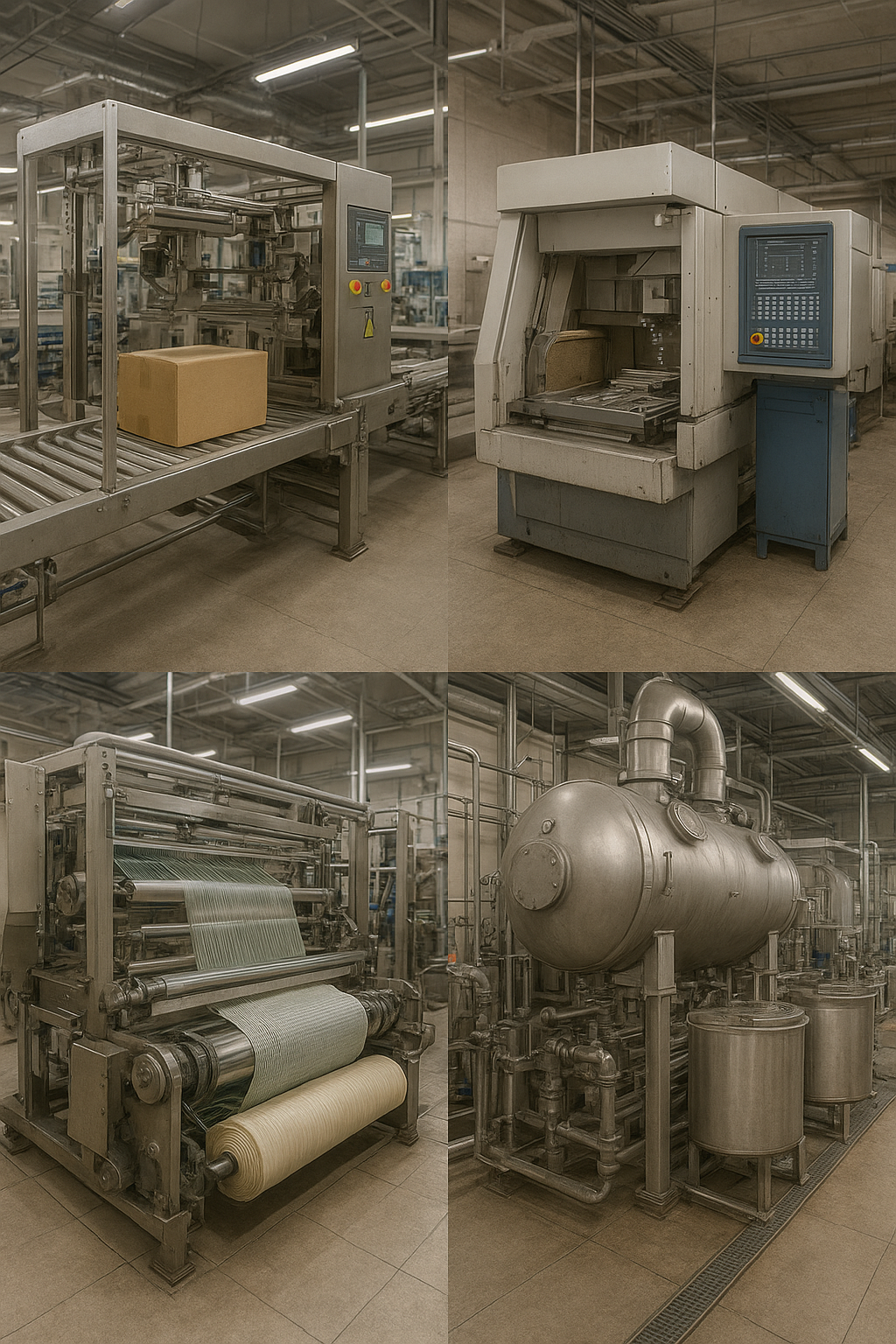

- Controls machinery and assembly lines in factories (e.g., automotive, food processing).Replaces manual/relay-based control with programmable logic.

- Manages continuous processes (e.g., chemical plants, water treatment).Monitors variables like temperature, pressure, and flow via sensors.

- Coordinates motors, servos, and actuators (e.g., conveyor belts, robotic arms).Used in CNC machines and packaging systems.

- Implements emergency stops (E-stops), light curtains, and safety interlocks.Detects faults and triggers alarms or shutdowns.

- Collects data from sensors for analysis (e.g., OEE tracking, predictive maintenance).Interfaces with SCADA and MES (Manufacturing Execution Systems).

Industrial Automation

Process Control

Motion Control

Safety & Monitoring

Data Acquisition (SCADA Integration)

Key Applications of PLC

Manufacturing

Automotive: Welding robots, paint shops, assembly lines. Food & Beverage: Filling, labeling, and packaging machines. Pharma: Tablet pressing, sterilization, vial filling.

Infrastructure

Water Treatment: Pump control, chemical dosing and filtration. HVAC: Building temperature and ventilation control. Smart Grids: Power distribution and load management.

Machinery

Packaging Machines: Wrapping, sealing, palletizing. CNC Machines: Tool positioning, spindle control. Textile Machines: Looms, dyeing systems.

Energy & Utilities

Oil & Gas: Pipeline monitoring, pump control. Renewables: Wind turbine pitch control, solar tracking.HMI

Human-Machine Interface

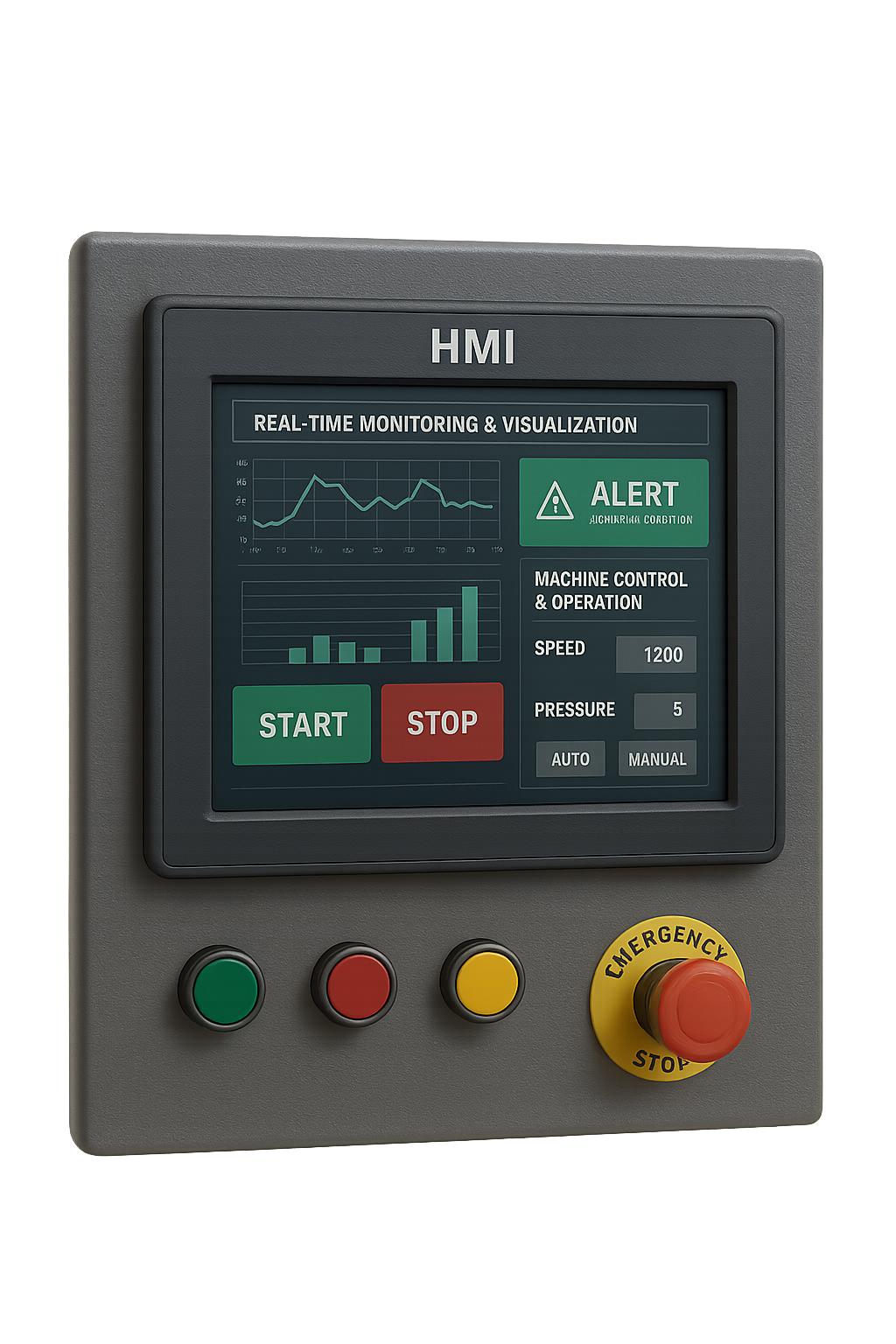

HMI: Human-Machine Interface

Human-Machine Interfaces (HMIs) are critical components in industrial automation, bridging the gap between operators and machinery. They provide intuitive visual control, real-time monitoring, and data interaction, improving efficiency and reducing errors.

Real-Time Monitoring & Visualization

- Displays live data (temperature, pressure, speed, etc.)

- Shows process trends via graphs and dashboards

- Alerts operators to abnormal conditions

Machine Control & Operation

- Start/stop machines with a single touch

- Adjust parameters (speed, pressure, timing)

- Switch between automatic & manual modes

Fault Detection & Alarms

- Visual/audible alerts for malfunctions

- Error logs with troubleshooting guides

- Reduces downtime with quick diagnostics

Data Logging & Reporting

- Records production data for analysis

- Generates reports (OEE, downtime, efficiency)

- Helps in predictive maintenance

Improved Safety & User Accessibility

- Password-protected access levels (operator, engineer, admin)

- Emergency stop controls

- Simplifies complex processes for non-technical users

Special Third Party Devices

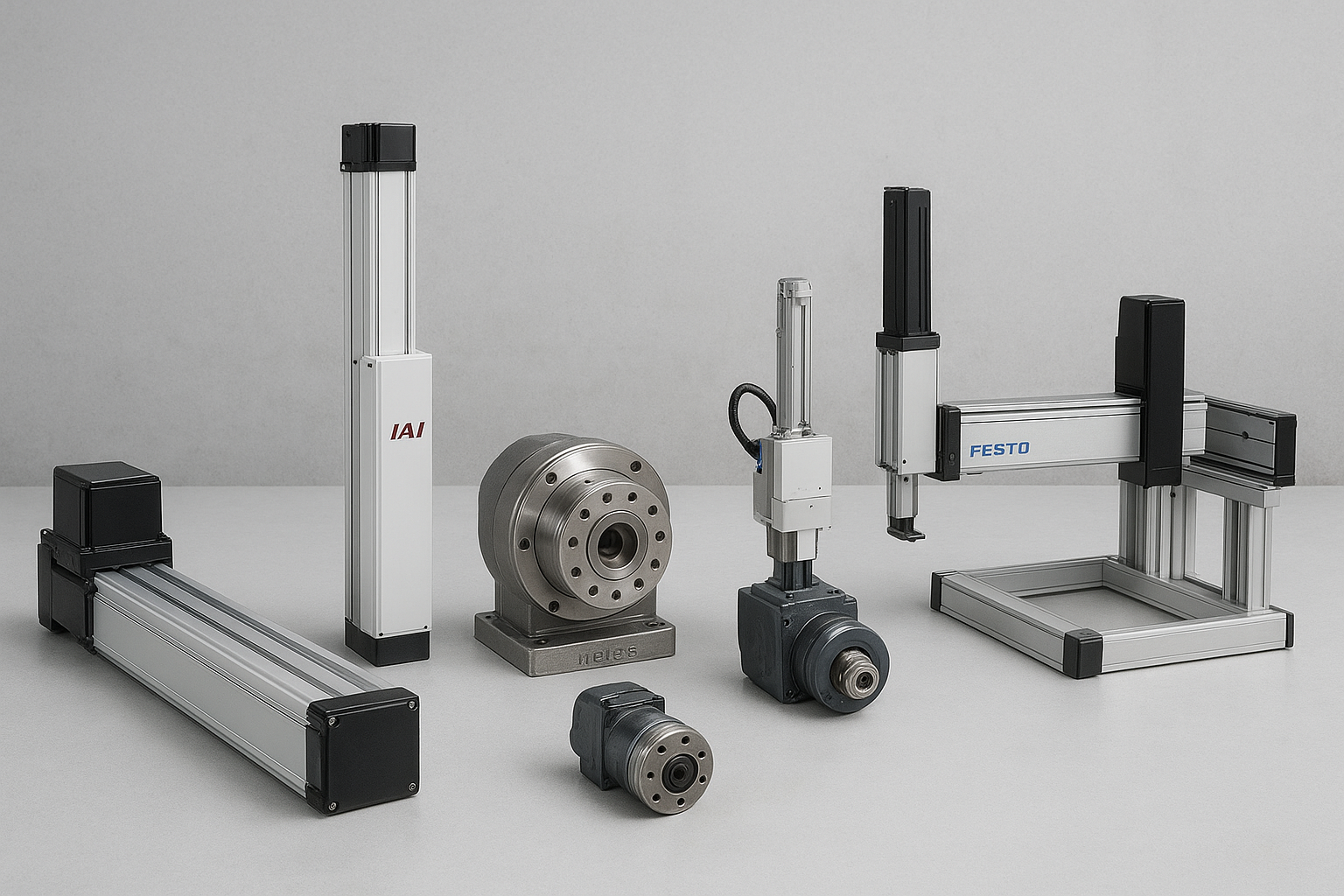

Motion Control & Positioning

- Thomson, IAI (Linear Actuators)

- Weiss, Camco (Rotary Indexers)

- Festo, Bosch Rexroth (Pick-and-Place)

- IAI, Bosch Rexroth (Cartesian Robots)

- Aerotech, Parker (Gantry Systems)

Industrial Robots & Cobots

- Fanuc (LR Mate, CRX)

- ABB (IRB, YuMi)

- KUKA (KR Agilus, LBR iiwa)

- Yaskawa (Motoman, HC10)

- Universal Robots (UR3e, UR10e)

Vision Inspection Systems

- Cognex, Keyence, Omron

- Basler, SICK

Barcode & RFID Readers

- Zebra, Datalogic, Honeywell

- Balluff, Turck

Nut Runners & Torque Tools

- Atlas Copco, Ingersoll Rand

- ESTIC, Bosch Rexroth

- Dai-ichi Dentsu

Leak Testers

- CTS, ATEQ, Cosmo Instruments

- Uson, Inficon

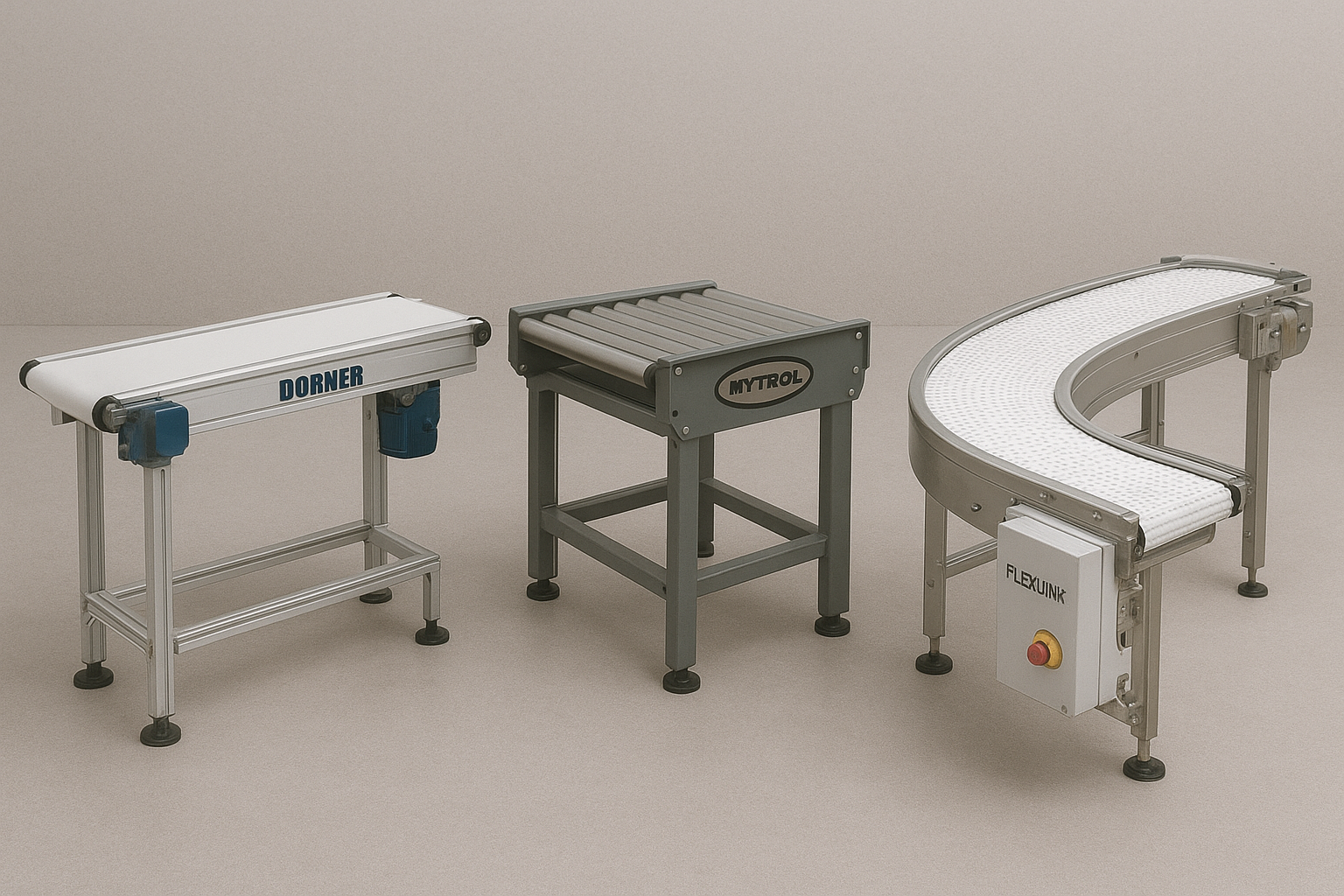

Conveyors & Material Handling

- Dorner, Hytrol, FlexLink

- B&R, SiemensK

Welding & Soldering

- Fronius, Lincoln, Miller

- Panasonic, OTC Daihen

Labeling & Marking

- Videojet, Domino

- Matthews, SATO, Weber

Pneumatic & Hydraulic

- Festo, SMC, Parker

- Bimba, Norgren

Temperature Control

- Watlow, Omron, Eurotherm

- Rex Controls, Despatchs

Specialized Assembly Tools

- Deprag, Desoutter (Screwdrivers)

- Schunk, Promess (Press-Fit)

- Baltec, Gesipa (Riveting)

- Scheugenpflug, Durr (Gluing)

Packaging & Labeling

- Bosch, Triangle (VFFS)

- Schneider, Brenton

- Fanuc, KUKA (Palletizers)

- Lantech, Ossid (Shrink)

- Mettler Toledo, Ishida

Electrical Testing

- Hipotronics, Chroma (Hi-Pot)

- Keysight, Megger (LCR/Insulation)

- Fluke, Teradyne

Energy Monitoring

- Yokogawa, Schneider, Fluke

- ifm, Balluff (Sensors)

- Eaton, APC (UPS)

- SMA, Fronius (Solar)